I have a question for you. We use the stuff all the time, but do you really know what

plastics are? I mean really know. I definitely didn't until this past year when I took a course on materials science that covered the nature of polymers beyond what is traditionally taught about just joining a bunch of monomers together into strings. So let’s take a

closer look at a material that has revolutionized the modern age.

Plastic is a broad term for a number of synthetic polymers with varying structures, properties, origins and chemical compositions. The properties of plastics vary according to three major

factors: chemical composition, tacticity and structure. Chemical composition as

a factor is fairly obvious since the different types of plastic we make vary

in make up. Composition affects properties of a plastic such as

the range of temperatures in which it maintains its structure. Polyethylene’s (PE, No. {2,4})

melting temperature (Tm) is around 115-130°C while polypropylene’s (PP, No. 5) Tm is around 130-170°C.

The only difference between these two polymers is an extra methyl group every other

backbone carbon in the case of PP. Chemical composition also informs how a

polymer is produced. Polyethylene terephthalate (PETE, No. 1), the plastic most water

bottles are made of, is synthesized through the transesterification of

terephthalic acid and ethylene glycol while many other polymers such as PE, PP

and polystyrene (PS, No. 6) are produced by free radical polymerization. Copolymers, or

polymers made with more than one monomer type, also exist in a variety of forms (block, graft, random and alternating) with more limited usage.

Fig. 1: Free radical polymerization of PS (California State University, Dominguez Hills)

Fig. 1: Free radical polymerization of PS (California State University, Dominguez Hills)

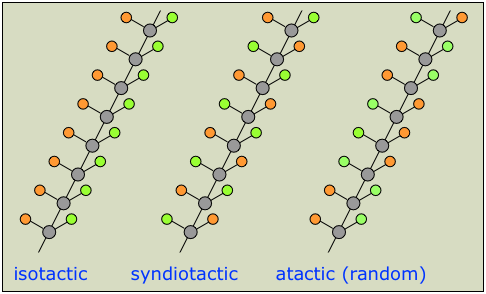

Polymer tacticity is another property of plastics, but one you usually don't hear about. Tacticity relates to the organization of monomer units

within polymer strands. There are three categories of polymer tacticity:

isotactic, syndiotactic and atactic polymers in order of increasing

variability. Isotactic polymers are comprised of monomer units all connected in

the same way to each other. Syndiotactic polymers have every other monomer unit

in the same orientation and atactic polymers are oriented any which way.

Fig. 2: Isotactic, syndiotactic and atactic polymer models (University of California, Davis)

Different synthesis methods affect the tacticity of the produced polymer, for example the use of metal-catalyzed polymerization reactions may enact more stereospecific polymer synthesis [1]. Tacticity

mainly affects whether or not a polymer can form crystalline regions. Isotactic PS, for example, is more likely to form crystalline regions through pi-stacking

than atactic PS is. Plastic performance is also sometimes affected directly by

tacticity, as with isoprene rubber. Natural isoprene rubber is isotactic in

that it is comprised entirely of cis-double bonds, which make it springy.

Atactic isoprene rubber or isotactic trans-polyisoprene rubber are relatively unspringy

[2].

Fig. 2: Isotactic, syndiotactic and atactic polymer models (University of California, Davis)

A plastic's three-dimensional polymer structure has a lot to do with the

macroscopic properties of a plastic. Polymers exist as spaghetti-looking chains

of controllable length that bundle and stack into a giant mess. Each chain can

be linear, branched, dendritic or cross-linked to other chains. When pulled upon

intensely, linear polymer chains slide out from underneath each other and cause

plastic deformation. Branched or dendritic polymer chains can make this harder to do, and

cross-linked polymer chains, like vulcanized isoprene rubber, can be extremely hard to

plastically deform (not a pun, I swear. It’s a type of deformation, along with elastic, related to a material’s tensile strength).

Fig. 3: Some possible polymer morphologies (Nature)

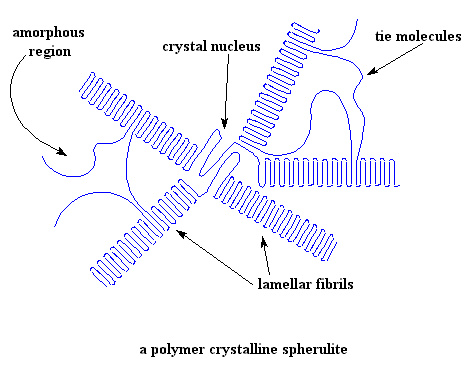

But if this is true, why does high-density polyethylene (HDPE, No. 2), made of linear polymer chains, have a lower tensile strength than its cousin branched low-density polyethylene (LDPE, No. 4)? This is due to crystal packing. When polymer strands organize, they form microcrystalline regions surrounded by amorphous, glassy regions.

Fig. 4: Crystalline and amorphous polymer structure (Polymer Science Learning Center)

Being linear allows HDPE to organize into a higher crystalline content than LDPE, and the extra intermolecular forces associated with these crystalline regions makes HDPE harder to deform than its other form. Fun fact, polymer crystallinity also has an effect on opacity in the same way the amorphous nature of glass causes its transparency, crystalline regions generally being more opaque than amorphous regions.

Due to their low capacity for biodegradation, the ubiquitous use of plastics in our society poses a serious problem for many environmentally-concerned individuals, and for good reason. Current plastic recycling programs are, to be frank, lacking, and this is majorly brought on by the economic limitations of recycling. Cultural attitudes towards sorting trash and recycled products also affect the efficacy of recycling programs. However, grass-roots activism and local- and national-level legislature are quickly changing opinions on the matter of plastic recycling. Knowing which plastics are recyclable (PETE, No.1, and HDPE, No. 2, only in many areas) will help to reduce the cost of sorting recyclables with a little effort, and public pressure for wider recycling programs may light a fire under companies to increase recycling, assuming the science exists. Research related to the synthesis of biodegradable polymers has picked up in recent years to produce products like polylactic acid (PLA, No. 7 (other)), but subsidies or funding is always welcome with science. If you're interested, these are things to talk to your local government representative about.

Fig. 3: Some possible polymer morphologies (Nature)

But if this is true, why does high-density polyethylene (HDPE, No. 2), made of linear polymer chains, have a lower tensile strength than its cousin branched low-density polyethylene (LDPE, No. 4)? This is due to crystal packing. When polymer strands organize, they form microcrystalline regions surrounded by amorphous, glassy regions.

Fig. 4: Crystalline and amorphous polymer structure (Polymer Science Learning Center)

Being linear allows HDPE to organize into a higher crystalline content than LDPE, and the extra intermolecular forces associated with these crystalline regions makes HDPE harder to deform than its other form. Fun fact, polymer crystallinity also has an effect on opacity in the same way the amorphous nature of glass causes its transparency, crystalline regions generally being more opaque than amorphous regions.

Due to their low capacity for biodegradation, the ubiquitous use of plastics in our society poses a serious problem for many environmentally-concerned individuals, and for good reason. Current plastic recycling programs are, to be frank, lacking, and this is majorly brought on by the economic limitations of recycling. Cultural attitudes towards sorting trash and recycled products also affect the efficacy of recycling programs. However, grass-roots activism and local- and national-level legislature are quickly changing opinions on the matter of plastic recycling. Knowing which plastics are recyclable (PETE, No.1, and HDPE, No. 2, only in many areas) will help to reduce the cost of sorting recyclables with a little effort, and public pressure for wider recycling programs may light a fire under companies to increase recycling, assuming the science exists. Research related to the synthesis of biodegradable polymers has picked up in recent years to produce products like polylactic acid (PLA, No. 7 (other)), but subsidies or funding is always welcome with science. If you're interested, these are things to talk to your local government representative about.

So there you have it, a brief overview of the chemical and structural background of plastics (and a little bit on the side). Plastics are quite complicated and therefore impossible to talk about in depth through any medium shorter than a book, but if you want to hear more about specific aspects of polymers let me know in the comments and I’ll be happy to do so. Thanks!

No comments:

Post a Comment